EL POAIG apron

EL POAIG apron

¡Menos de 30 unidades disponibles!

Product Description

Product Description

From the land to the table (production process)

From the land to the table (production process)

Achieving excellence in any field means putting all your passion, study, and resources into it. To achieve excellence in our oils, we must control every phase of the process down to the smallest detail. This begins once the olive harvest of the previous season has been completed.

The first task is pruning, which takes place in January and February. Through pruning, we remove old, unproductive branches, ensuring good aeration and sunlight, and relieving the olive tree of excess "work" so it can direct its energy towards the branches that will grow stronger, produce better blossoms, and yield the best fruit with an optimal pulp-to-pit ratio. We secure the harvest for the next season.

If everything goes well, the next natural process will be pollination and fertilization. During this time, the fruit sets. Naturally, a competition for nutrients begins between fertilized flowers, unfertilized ones, and new branches that will produce the olives for the next harvest.

This is a crucial and delicate moment. It is important to prevent any pest from causing defoliation or flower drop. To address this, EL POAIG's technicians conduct soil and leaf analyses to determine the olive tree's nutrient and water needs, reducing stress and ensuring a better harvest.

An excess of fruit can inhibit flowering for the following year, a phenomenon known as "olive tree alternate bearing."

Pest and disease control is continuous throughout the growth and ripening of the fruit, determining both the quantity and quality of the harvest we aim to achieve.

The fruit grows until autumn when the skin color begins to change, and the processes of oil synthesis and accumulation, known as "lipogenesis," start.

From this point on, random collections are made weekly to extract oil from the fruits, monitor the oil content, and optimize the organoleptic characteristics of the oil until reaching the balance that Manuel Arnau, EL POAIG’s master miller, determines for obtaining excellent quality oils.

When the time for harvesting arrives, Manuel coordinates the work to ensure the shortest possible time between fruit detachment and its extraction and milling.

The harvesting is done using mechanical milking techniques that prevent branch breakage and olive bruising, or with manual vibrators. The trees selected for harvesting are supervised, and the method to be used is determined.

Millenary olive trees have a large canopy, often exceeding 150 m². For a single tree, various harvesting techniques may be used depending on orientation, fruit load, access difficulty, and aeration.

The harvested olives are transported to the mill. Once the fruit arrives, it undergoes another quality control, discarding batches that show bruises, broken skin, or ripeness levels beyond the required standards. The olives are then destemmed and pass to the mill, where they are crushed to the appropriate size based on the water-to-oil ratio of the fruit.

Throughout the process, we minimize aeration to avoid oxidation. For this, we use the highest technology in oil extraction.

From the mill, where the fruit spends only seconds, it moves to the mixer, where it remains at room temperature. At no point does the temperature increase, and the mixing lasts for 20 to 30 minutes. The "master miller" determines the appropriate mixing time based on how the fruit has grown, the amount of irrigation or rainfall, nutrients, and the organoleptic evaluation that we carry out, which determines the fruitiness, bitterness, and pungency of the oil we aim to produce.

After the mixing time, the paste is injected into the horizontal centrifuge, where the oil is separated from the rest of the olive, all with a minimum injection rate.

This produces a clean, green oil, and discards the part of the oil that, during the separation phase, is too close to the paste.

Low injection rates and minimal exhaustion provide clean oils of the highest quality, with an average yield of 11% to 14% oil per kilo of olives.

These are low yields, but they ensure that EL POAIG oils are of excellent quality.

For oils with high astringency and/or moisture, a second pass through the vertical centrifuge is recommended to achieve a smoother palate without losing polyphenols.

EL POAIG oil is now ready and goes directly into stainless steel tanks, kept in the dark and inertized with noble gases—nitrogen or argon—and without oxygen to preserve all its properties.

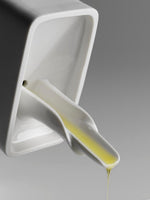

Bottling is done directly from the tank using a system designed by EL POAIG engineers for the exclusive white porcelain bottles.

EL POAIG oils are bottled on demand. We do not store bottled oils, ensuring the highest quality and the shortest time spent in the bottle, minimizing potential degradation processes and preserving the organoleptic properties of our precious olive juice.

All this makes EL POAIG oils considered among the best olive oils in the world.

FAQ

FAQ

Couldn't load pickup availability